How to remove pumice stones from denim washing

Several methods, one common goal: make the denim industry a more sustainable one

This article was made in collaboration with Mattia Magnoni, Technical Product Developer of Garmon Studio.

The use of pumice stones in denim washing is a quite old-fashioned practice

It was invented during the ’70-’80 to to transform a raw denim jean in a vintage one, giving it a worn and used look. But the use of pumice stones has several drawbacks, particularly in terms of logistic costs and environmental pollution.

Since the 1990s, the introduction of enzymes in the process allowed to enhance the stone wash effect in denim and jeans, decreasing the process time and increasing the efficiency of denim laundries all over the world.

Today, thanks to technological improvements and increasingly powerful enzymes, it’s possible to eliminate 100% the use of pumice stones in the denim washing. However, despite the new technologies, many laundries still prefer to wash using pumice stones, claiming that they are cheaper, and they give better results, or just because they are familiar to the process.

But, as as stonewashing with pumice stones is harmful to the environment, the implementation of alternative methods to perform denim stonewashing has become utterly necessary.

The process of stone washing with pumice stones pollutes

The textile industry is one of the most pollutant businesses of the world, and the use of pumice stones is contributing to reduce it by no means.

The stones are taken out of the natural environment in an exploitative way, destabilizing the ecosystem. Furthermore, the transportation of pumice stone is pollutant, as it requires many heavy trucks all over the world emitting CO₂ and other greenhouse gases. A lot of space is required in the laundries to storage all the pumice stones. During the washing process, an enormous amount of water is needed, and the baths are very time consuming. Most of the times, at the end of the process the stones - stained with indigo and other chemicals - are improperly discarded back into nature, along with the sludge that is formed inside washing machines.

Besides the environmental aspects, there are other critical points related to the stone washing, such as the impact on the workers and on the process time:

The workers must carry heavy bags of stones every day to load into the washing machine

The process time is extended because immediately after the bath, an additional process of removing the stones from every garment is necessary

Stone washing increases process losses and garment second choice, as it often causes damage to the apparel

The stones also cause a great amount of wear and damage to the washing machines, reducing their lifespan

Enzymes address the problems of pumice stones

Enzymes based on cellulase and other innovative compounds can be used to achieve the same level of abrasion that you get with pumice stones.

Available in powder, granular or liquid form, enzymes are added directly to the washing machine, giving to jeans and denim garments the vintage look they are famous for.

By replacing pumice stones with new generation enzymes, such as our kemzymes line, all these problems are solved or reduced:

- no inappropriate exploitation of natural resources

- reduction of heavy transportation and the related CO₂ emission

- more space available in the warehouse

- no disposal of sludge in the wastewater

- reduced risks for denim laundries’ workers

- no damage to washing machines

Amazing looks can be achieved with this process, reducing also process time and energy, resulting in a positive balance of CO₂ reduction in the atmosphere.

Besides the use of enzymes, there are alternative, new technologies that can be used to replace pumice stones in denim washing.

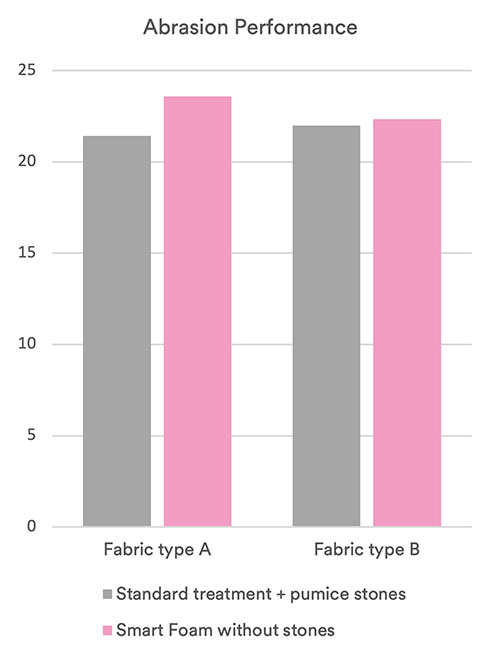

A great example is smart foam, the water saving made easy system designed by Garmon. According to the industrial tests, thanks to the low liquor ratio the enzymatic washes performed with smart foam produce a better abrasion compared to the standard treatments.

This means that with a smart foam enzymatic washing with no pumice, you can match the level of abrasion of a standard mild treatment requiring pumice stones, saving up to 80% of water in the treatment.

If water saving is not your priority, there are other new enzymes applications that can be used to effectively remove pumice stones from denim washing. For example, our new kemzyme ar is designed to be applied on wet garments after an initial desizing phase. By working with a reduced liquor ratio, kemzyme ar gives a strong abrasion on jeans’ panels and seams, producing a great vintage look without the stones.

To sum up

It is quite clear that the process of stone washing jeans causes enormous damage to the environment, and has major operational issues.

Therefore, the use of enzymes is becoming more and more important to achieve the same looks without the use of stones. When combined with advanced technological processes, such as smart foam technology, the results are enhanced both for the producer and the environment.

At Garmon we stay true to our slogan "Stones belong to nature", and we know that we must keep working on that if we want the denim washing industry to become a more sustainable one.

Want to know more on our treatments for denim?