Behind the scenes: Quality Assurance goes beyond certifications

Are you aware about the difference between a certified product and a quality assured product?

This article was made in collaboration with Silvia Boneschi, Regulatory Specialist at Garmon.

As sustainability trends move forward, chemicals certification for denims and jeans production has become widely promoted. But are you aware about the difference between a certified product and a quality assured product? These are separate but often confused topics.

The most classic misconception is to assume that certified products are a guarantee of the product's quality. See below the differences between certification and quality assurance.

Certified product:

Most certifications refer to a third-party endorsement of a given standard. In the case of chemicals for denim, certifications are very much related to sustainability, and the safety of the product in the environment and during its use. Certification does not refer to the day-to-day inspection of a production, although some standards include quality control as a mandatory requirement during the approval process. To learn more about certifications, click here to read the article Chemically certified: why we should value certifications in textiles.

Quality-assured product:

Not necessarily linked to sustainability, but rather to quality. Quality assurance is a system implemented in factories that aims to ensure that a product is manufactured and delivered following certain quality standards, which are monitored through continuous testing, inspections, and audits. Quality assurance includes daily actions aiming to deliver the final product with guaranteed quality to the customer.

To clear up any doubts about the difference between certification and quality assurance, let's look at an example that can help you differentiate these two terms.

Potassium Permanganate

Potassium permanganate has been widely used in the jeans washing industry. This chemical is considered hazardous to the environment, as it has a high degree of toxicity to marine life. Permanganate is not certified and will never be certified by regulators who have sustainability as major concerns. However, companies that sell potassium permanganate can still assure that the delivered product has exactly the desired functionality according to its identity parameters. In other words, permanganate has no certification, but it can have quality assurance.

Avol Oxy White

On the other hand, Garmon's avol oxy white is a chemical product that replaces potassium permanganate in the application as a bleaching agent in jeans. avol oxy white is a product certified by Bluesign® System Partner regarding sustainability and environmental safety. In addition to certification, Garmon produces avol oxy white with high quality standards, ensuring that the delivered product has the expected characteristics. It is an example of a certified and quality assured product.

Now that we have clarified the difference between certification and quality assurance, let's dig a little deeper into quality assurance.

Once the critical quality parameters of a product have been defined, efforts are made to ensure that the product conforms to those parameters and, thus, reaches customers with the right and highest quality standards. To achieve this goal, the first step is to ensure quality assurance with regard to input control. For this purpose, significant work is done from the very beginning of the production chain, with the definition of suitable and reliable suppliers. These are able to supply raw materials with lower risks to humans and the environment, complying with the most important RSL and ZDHC MRSL.

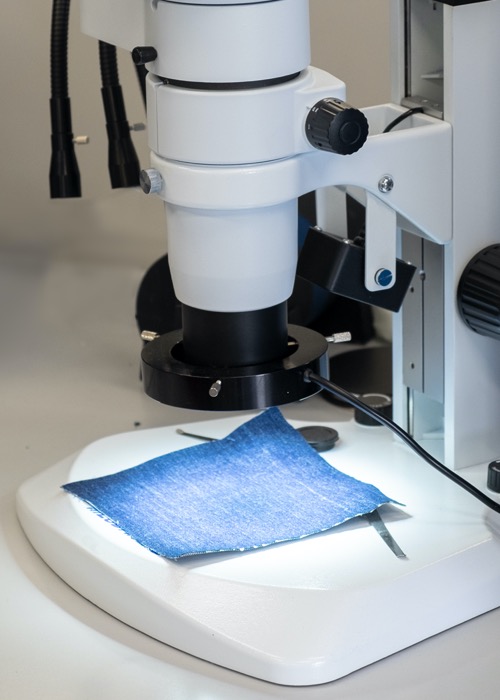

Several analyses should be done on the raw materials, as happens inside Garmon's laboratories. Every day several physical-chemical analyses, such as pH, moisture, dry matter, enzymatic activity, and others are performed, assuring that the raw materials are in accordance with the suppliers’ certificate of analysis. The next step in the quality assurance concerns the processing of chemicals. Temperatures must be appropriate, time must be respects, mixing speeds must be on track, recipes must be followed with accuracy, and employees must act in a safe way.

Finally, with the final product in our hands, an additional series of analyses must be conducted to ensure that it will properly reach the final customers. Some examples of the major analyses can be basic physical-chemical analyses, such as pH, viscosity, refractive index, and dry matter. Those are crucial to ensure the quality of the finished goods.

Lastly, we reinforce that Garmon seeks to have a portfolio with more certified products and 100% quality assured products through our quality management system.