Biopolishing

Cellulase-based products for enzymatic biopolishing of denim, cotton and blends at different temperatures and pH conditions

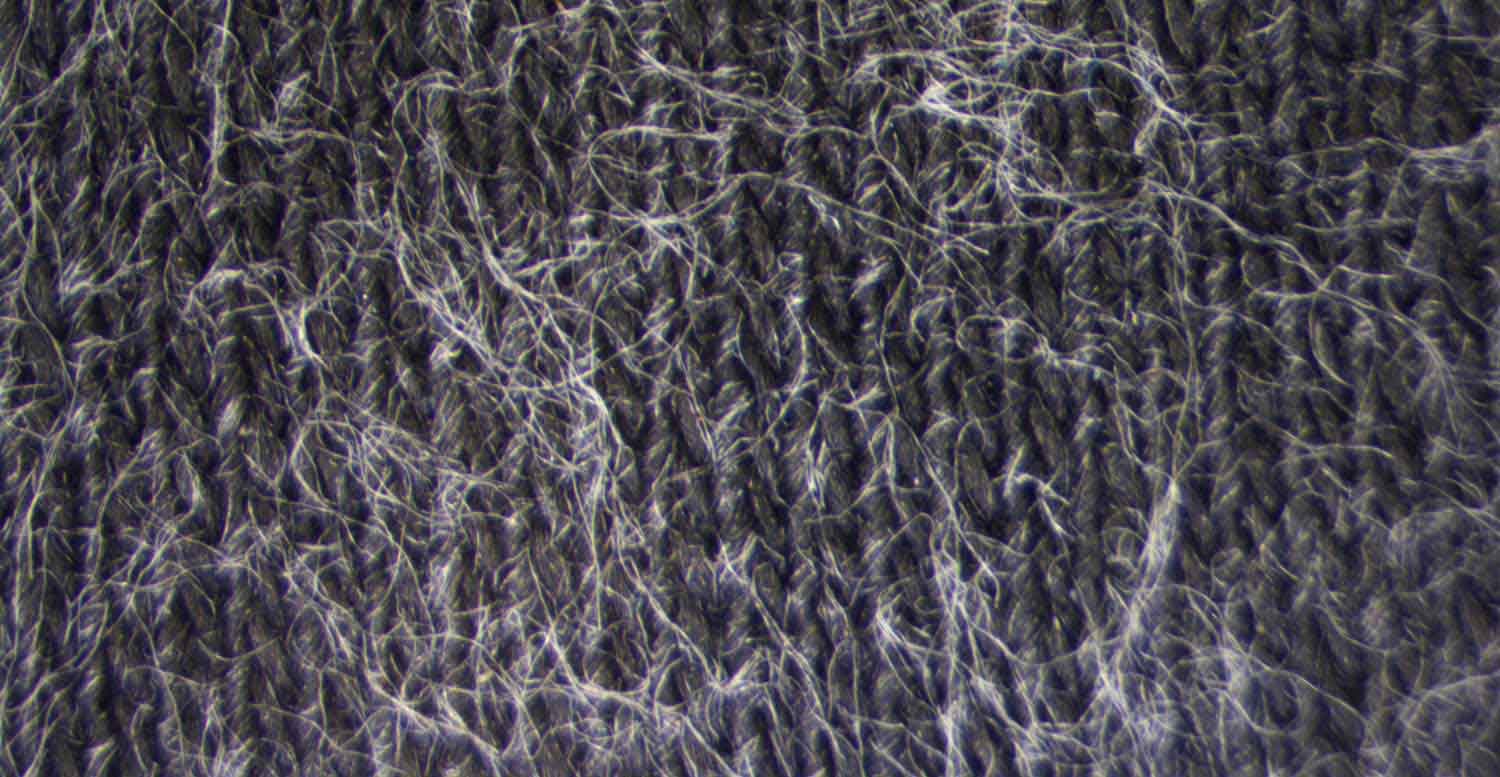

Biopolishing is a textile process that enhances fabric quality by the elimination of superficial hairiness.

Significantly reducing pilling, biopolishing gives garments a shiny and bright look, making the fabric texture more obvious, and provides a more pleasant hand feel.

An incorrect procedure or an inadequate enzyme can give problems of indigo back-staining on denim garments and reduce the fabric’s mechanical strength.

Garmon Chemical’s auxiliaries for biopolishing are specifically developed to provide:

- brighter shades and higher contrast in abraded areas

- minimal indigo bleeding

- less back-staining

- minimal environmental impact

- less corrosion of metal accessories

They are designed to work in low and medium temperatures, in acid or neutral conditions.

Products for Biopolishing:

kemzyme bio 1

Our innovative biopolishing agent in powder form. Great performance and superior stability than liquid formulations. Temperature range: 30-50°C.

- bluesign

- ZDHC level 3

hidros 7

High concentration enzyme for biopolishing of denim, cotton and blends. Optimum use conditions: 50-60°C, pH 4.5-5.5.

- bluesign

- ZDHC level 3

hidros rtl

Innovative liquid cellulase for biopolishing of denim, cotton and blends operating at room temperature and neutral pH. Used on denim with no back-staining and on dyed garments with no shade change. Optimum use conditions: 25-30°C, pH 6-7.5.

- bluesign

- ZDHC level 3

- Nimbus

- Smart Foam

hidros ted

Liquid cellulase for biopolishing of denim, cotton and blends operating at low temperature and neutral pH. Used on denim with no back-staining and on dyed garments with no shade change. Optimum use conditions: 40-50°C, pH 6-7.

- bluesign

- ZDHC level 3

hidros 4000-n

High concentrated formula for enzymatic biopolishing of fabrics in cellulosic fibers, at low temperature and neutral pH.

- bluesign

- ZDHC level 3